Showroom

Forged Shafts are mechanical parts produced by the forging process, where metal is formed using localized compressive forces, usually delivered by a hammer or a press. Their dependability, coupled with the fact that they can be tailored to individual specifications, renders forged shafts a popular option for most industrial uses. They are engineered to support high rotational loads and torsional stresses and are thus used in heavy-duty applications such as gears, motors, turbines, and automotive systems.

Gear Blanks are the raw, unfinished material pieces from which gears are manufactured using processes like hobbing, shaping, or milling. They are made of high-grade materials that impart the required strength and wear resistance to the finished gears so that they can withstand heavy loads, high torque, and tough operating conditions. They are employed to manufacture high-precision gears utilized in aircraft engines, landing gear systems, and other safety-critical systems where reliability and performance are critical.

Industrial Shafts are mechanical fittings that transfer torque and rotational energy in equipment and machinery. Industrial Shafts withstand rotational forces, mechanical stresses, and adverse environmental conditions and form essential parts for numerous applications. They are customarily fabricated of high-strength materials like stainless steel, alloy steel, and steel and form essential parts used in automotive industries, manufacturing companies, mining sector, energy equipment, and machineries.

Forging Parts are parts that are produced by the forging process, a manufacturing method in which metal is formed by compressive forces. The forces are usually applied with hammers or presses. Forging increases the strength of the material by aligning the grain structure of the metal, making it suitable for high-performance applications where reliability and durability are critical. These are extremely durable, with wear, fatigue, and impact resistance.

Gear Shafts are mechanical parts that are vital in transferring rotational motion and torque from one gear to another in machines, vehicles, and other mechanical systems. They are vital in most industries such as automotive, aerospace, industrial machinery, and power generation. They are utilized to bear and transfer the motion of gears to ensure smooth running and proper alignment.

Steel Ring is a round metal piece constructed of steel, widely utilized in numerous applications because of its strength, durability, and versatility. These are very versatile, with varying designs and sizes that can suit different application needs. They are used in different industries such as automotive, construction, aerospace, energy, and manufacturing.

Forged Blocks are dense, rectangular or square-shaped metal parts that are manufactured using the forging process. They are widely applied in industries that need parts with high strength and durability, such as aerospace, automotive, heavy machinery, and energy industries. The forging process improves the mechanical properties of the material, and forged blocks are stronger, more durable, and more resistant to fatigue and wear than cast or machined blocks.

Steel Hub is a very essential mechanical part which is widely used in many different industries, but mainly in car, machinery, aircraft, and equipment industries. Steel hubs are strong, reliable, and resist heavy loads and thus are the core part required in systems requiring high performance. Being manufactured precisely, steel hubs maintain proper fitting, smooth working, and minimal resistance, which is vital for rotating machinery and systems.

Forged Rings are round metal pieces that are produced through the forging process, where metal is heated and formed under pressure to create a strong, tough, and high-quality item. They are widely utilized in applications where parts are subjected to high stress, high temperatures, or harsh environments. They are utilized in various industries because of their superior mechanical properties, such as high strength, toughness, and wear resistance.

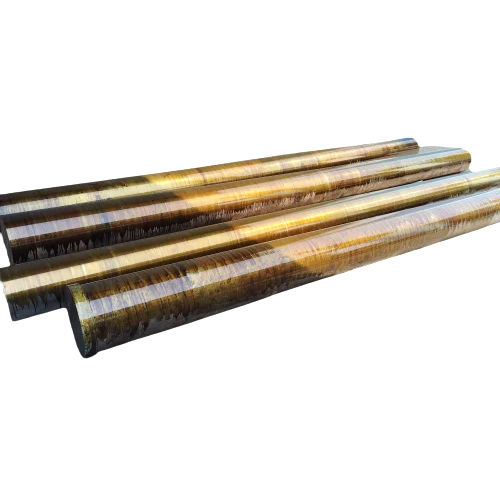

Brass Rod is a circular metal product made of brass, an alloy which consists mainly of copper and zinc. They are usually manufactured in extrusion or drawing processes and come in several diameters, lengths, and grades based on the application required. These find extensive use across industries because they possess a wonderful combination of mechanical properties, resistance to corrosion, and machining capability.

Ship Shaft is an important part of a marine propulsion system, employed to transfer mechanical energy from the engine of the ship to the propeller, enabling the ship to travel. The design and material of the shaft provide durability, efficiency, and safety, particularly in the demanding marine environment. They are large, high-strength parts with the capability of supporting large rotational forces and operation under extreme conditions.

Forged Gear Blank is a pre-formed, round metal block that is manufactured by the process of forging and serves as the raw material to be used for the production of gears. Forged gear blanks are extensively used in applications in which gears should be able to bear high stress, high torque, and severe environments. Metal is shaped with high pressure while undergoing the forging process, thus refining its grain structure, hardening it, and improving overall mechanical properties.

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free